Granitan

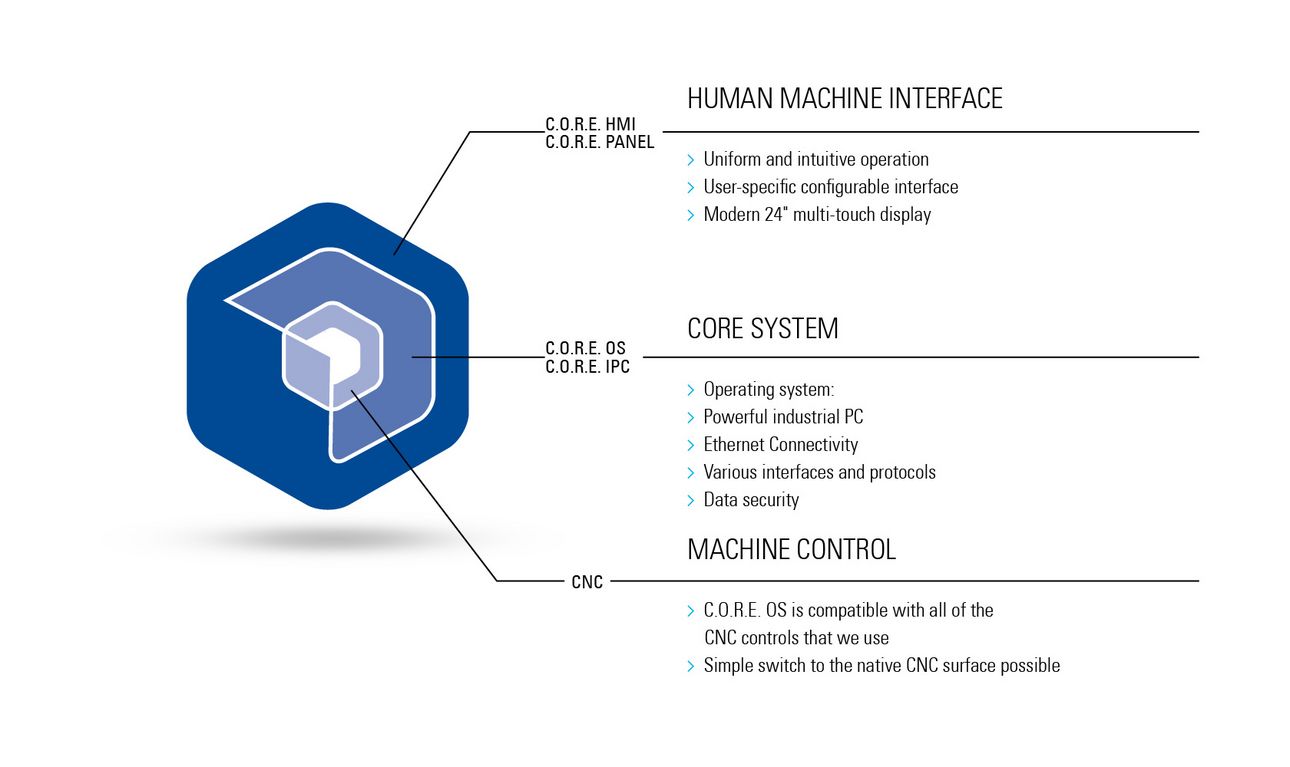

C.O.R.E. helps us make your production fit for the digital future.

C.O.R.E. helps us make your production fit for the digital future.

It is based on a new operating system, C.O.R.E. OS, which equips the machine with intelligence.

Fitted with the uniform C.O.R.E. software architecture from UNITED GRINDING, exchanging data between our UNITED GRINDING machines is easy. The integrated Umati interface can also be used to communicate with third-party systems. It also offers access to United Grinding Digital Solutions™ products directly on the machine, without requiring the installation of supplemental hardware.

C.O.R.E. not only establishes the technical foundation for this and other IoT and data applications, but it also forms the basis of revolutionary yet uniform operation.

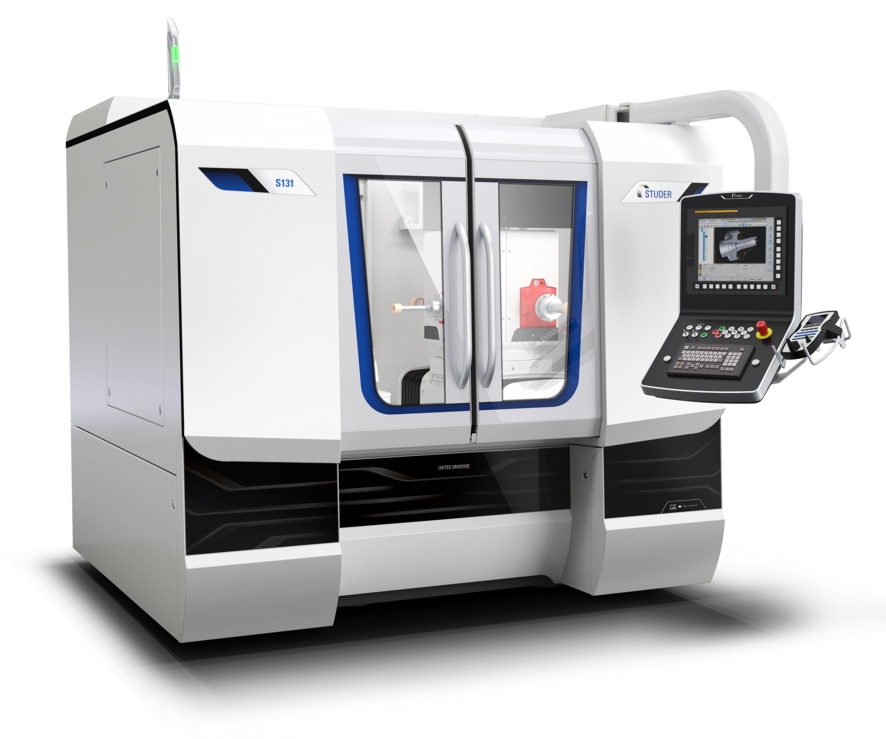

Technical specifications

- 24" Full HD multi-touch display

- 16-position rotary override switch

- Electronic key switch (RFID)

- Integrated front camera

- Bluetooth compatible

- 2× USB Ports

- Adjustable tilt

C.O.R.E. Panel – The future of operation

Intuitive

Thanks to intuitive design with self-explanatory icons, navigation through the machine menu and process steps is quick and easy. Instead of buttons, the user is presented with a modern, clearly arranged multitouch display.

User-friendly

Each user configures their user interface individually. It then loads automatically after the user logs in with a personalized RFID chip. If you leave the machine, the panel switches to “Dark Factory Mode”. Production progress and the machine state are also clearly visible from a distance. And thanks to the clever ergonomic design, the panel can easily be tilted and individually adjusted.

Efficient

The uniform and intuitive operating philosophy reduces training time. The configurable, role-specific interface helps prevent errors and increases the efficiency and quality of programming. Information can be exchanged quickly and in real-time via the integrated front camera and a Bluetooth headset. UNITED GRINDING Digital Solutions™ products can be managed directly on the panel.